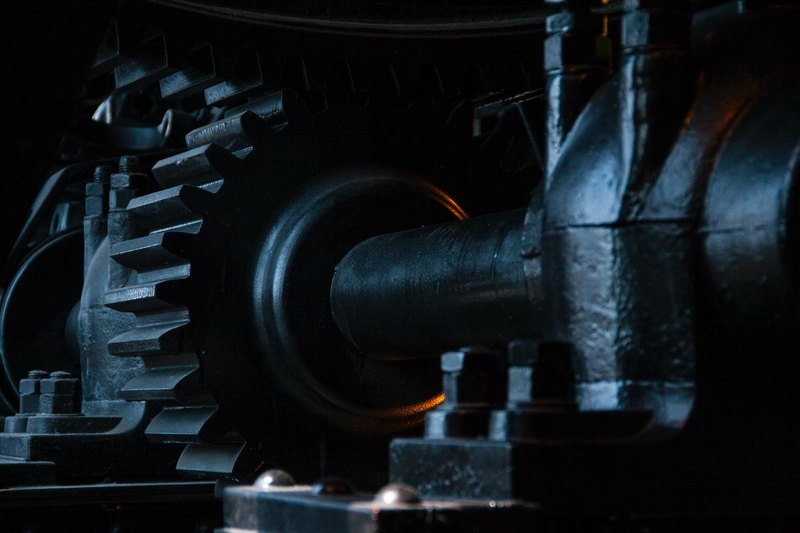

Gear Oil and Grease

Gear Oil Lubricants and Grease

Grease and oil are both common lubricants. The main difference between them is that grease consists of an oil AND a thickener. Typically, greases have a semi-solid to solid consistency.

Greases and gear oil need to provide adequate lubrication in all conditions such as hot and cold temperatures, heavy loading, wet and steamy conditions and indoor and outdoor environments. Contact us for more information regarding your gear oil and grease lubricants specifications

Gear Oil as a Lubricant

Oil is the best choice in the following circumstances or applications:

- applications that require extremely low torque or a narrow range of torque variation

- applications that exhibit high speeds and high operating temperatures

Grease as a Lubricant

Grease is a mixture of fluid lubricant and a thickener dispersed in oil. As a lubricant for bearings, grease is going to be the best choice in the following circumstances or applications:

- systems or applications where an oil product would not be retained

- applications with slower operating speeds

- applications that require an added seal of protection from contamination and moisture

Advantages of Grease over Oil

There will be instances when oil will be a better choice of lubricant for your application.

However, grease tends to be a better fit for some applications due to the following reasons:

✔︎ Ease of retention – stays in place

✔︎ Minimal application – reduced maintenance cost

✔︎ High reliability – historical reliability in electric motors

✔︎ Protection – helps keep out moisture and contaminants

✔︎ Clean – minimal leaking/dripping

✔︎ Greased for life – ideal for inaccessible bearing applications

Available from XMT

- Automotive oil and grease

- Industrial oil and grease

- Food grade oil and grease

- Equipment related to the oil and grease industry

- Environmental services and recycling – oil and grease industry

- 15W40

- Synthetic 10W40

- Synthetic 5W30

- SAE40

- Red rubber grease.

- Food grade grease.

- Food grade oil.

- Food grade grease 00.

- Seal grease.

- Kluber H1 grease.

- White food grade grease.

- Synthetic grease.

- SHC220 grease.

- SHC100 grease.

- Groz grease.

- Red synthetic grease.

- High temperature grease.

- BPW axle grease.

- Blue grease.

- Molly paste.

- Drawing lubricant.

- Drawing paste 700.

- Molybdenum disulphide.

- Copper paste.

- Copper grease.

- Graphite grease.

- 22G grease.

- Nickel grease.

- Moly lead oxide.

- Torqueing grease.

- Synthetic grease.

- 400gr tube grease.

- Non-melting grease.

- Bentonite grease.

- Wurth grease.

- Grease gun.

- GR33FD.

- Grease cartridges.

- Food grade oil

- Food grade grease 00

- Food grade hydraulic oil

- Aluminium cutting oil

- Soluble aluminium cutting oil

- Castrol Perfecto T 46

- Castrol Perfecto T 32

- Synthetic oil

- Wurth oil

- S10 pneumatic oil

- Food grade gear oil

- Synthetic gear oil

- Fluorinert electrical fluid

- Extreme pressure lubricants

XMT Specialised Products

Graphite grease (14%) trucks – 5th wheel

Trucks – 5th wheel

Rock drill grease

Mining

Food grade grease

Manufacturing lines for the food industry

High temperate grease

high temperature applications such as furnaces and for bearings.

Synthetic grease

All machinery requiring synthetic grease – higher grade greases from Group1 Base oils or synthetically derived bases

Transport Related Products

Load securing equipment

Chains, straps, tarpaulins etc.

Trailer equipment

Tailboards, electrical, air

Brakes

Need-To-Know knowledge

The objective of this page is to share basic knowledge about oils and greases.

This will benefit you by equipping you with basic need-to-know knowledge if you are in any way involved with Lubricants whether it be selling, advising or using/applying it.

Want to know more?

Click here to book a meeting to discuss.

This will include 3 lessons:

Lesson 1:

What is the function of oil and grease.

✔︎ Reduce friction between moving surfaces that are in contact

✔︎ Reduce heating

✔︎ Reduce wear and tear

✔︎ Control temperature

✔︎ Control corrosion

✔︎ Act as shock dampers (gears)

✔︎ Remove contaminants

✔︎ Forms a seal (grease) to prevent ingress of dirt

Lesson 2:

Grades and specifications.

We see many Grades, Specifications and Classifications on a variety of Products and it’s packaging, what are they and what does it mean?

Let us explain.

“W” - Winter

In short, if you see an expression such as 10W-40, the oil is a multi-grade which simply means that the oil falls into 2 viscosity grades, in this case 10W and 40. This is made possible by the inclusion of a polymer, a component which slows down the rate of thinning as the oil warms up and slows down the rate of thickening as the oil cools down.

Multi-grades were first developed some 50 years ago to avoid the routine of using a thinner oil in winter and a thicker oil in summer. For a 10w-40 to attain the specification target a 10W the oil must have a certain maximum viscosity at low temperature. The actual viscosity and the temperature vary with the viscosity grade but in all cases the lower the number, the thinner the oil.

For example a 5W oil is thinner than a 10W oil at temperatures encountered in UK winter conditions. This is important because a thinner oil will circulate faster on cold start, affording better engine protection and therefore lower long term wear! For a 10w-40 to attain the other specification target a 40 themoil must fall within certain limits at 100°C.

Other Grades

- API – American Petroleum Institute

- SAE – Society of Automotive Engineers

- SABS – South African Bureau of Standards

- SANS – South African National Standards

- SO – International Standards Organization

- EP – Extreme Pressure

- MIL-L – American Military Specification

- I.G.O – Industrial Gear Oil

CF, CH, CI etc.

- C – Stands for Combustion. (Diesel Engines)

- The higher the letter in the alphabet next to C, the higher the quality and the latest technology applied.

SF, SJ, SL etc.

- S – Stands for Spark. (Petrol Engines)

- The higher the letter in the alphabet next to S, the higher the quality and the latest technology applied.

- Most oils are combined Grades so it can be used in both Diesel and Petrol Engines e.g. CH/SJ

GL – Gear Lube

- GL-4, GL-5 – Basically means the higher the number the more EP Additives are present. For use of Gear Oils the correct GL-Number should be selected.

- Higher in this case is not necessarily better.

Viscosity

Viscosity is actually the Resistance of Oil to Flow. The higher the Viscosity the Higher the resistance to flow and vice-versa.

Additives

These are added to blended base oils to attain certain qualities that the final product needs to conform to.

Types of additives are:

- Viscosity Improvers

- Detergents

- Dispersants

- Oxidation Inhibitors

- Corrosion and Rust Inhibitors

- Friction Modifiers

- Anti-Wear Agents

- Extreme Pressure Additives (EP)

- Foam Depressants

- Pour Point Depressants

Hydraulic Oils

Although many manufactures of hydraulic fluid provide various grades of detergents and oxidation stability in the fluids they produce, the single factor that should weigh the heaviest in determining the best choice of fluid to use is viscosity.

Viscosity is also most often expressed as the fluid’s ISO number or grade.

- ISO 32, 46, 68, 100, 150, 300.

- Higher Quality Versions will indicate this by AW (Anti-wear), OSO (Agip), HVI(High Viscosity Index), S etc.

Mineral

Oil derived from refining Crude Oil.

Synthetic

Synthetic oil is a lubricant consisting of chemical compounds which are artificially made (synthesized) using chemically modified petroleum components rather than whole crude oil. Synthetic oil is used as a substitute for lubricant refined from petroleum when operating in extremes of temperature and load, because it generally provides superior mechanical and chemical properties to those found in traditional mineral oils.

Lesson 3:

Grease, Why Grease?

Greases are typically applied in areas where a continuous supply of oil cannot be retained, such as open bearings or gears.

Factors to be considered when selecting a suitable grease are operating temperatures, water resistance, oxidation stability etc. The second factor, not less important, are the grease’s characteristics, including viscosity and consistency.

- A lubricating grease consists of a base oil, performance additives and a thickener which forms a matrix that retains the oil in a semisolid state. Most grease thickeners are soaps, i.e. lithium, calcium, or aluminium soap.

- Complex soap greases have superior temperature resistance and are commonly usable up to 180ºC, at which the mineral oil vaporizes. A smaller number of greases, restricted to very special applications, are manufactured with non-soap thickeners such as organic-clays, poly-urea or silica (synthetic) compounds.

Oil =

Oil =

Oil?

Oil = Oil = Oil?

No…

Always make sure you choose the right oil with the correct specification for you or your customer’s application.

We have not even scraped the surface of what Lubrication is about

An Information Pack to supply more information and give more insight will be handed out.

It contains:

- Contact Information

- More Info on Grades and Specifications

- A Matrix of AGIP products, short descriptions and available pack sizes

XMT Blog

Hydraulic Systems

High output force Standard components Precise control Very complex final movements are achievable Fluid circulation ensures heat removal Low overall efficiency Considerable capital costs General characteristics not favourable for rapid movements Possible leakage could...

Cleaning Chemicals

Cleaning Chemicals We create our own environment, so we get exactly what we deserve. Chemicals are needed for a variety of reasons, but it is our responsibility to ensure that we don’t damage our surroundings. Aesthetics, safety, hygiene and maintenance – CLEAN +...

Engine Hydraulic and Synthetic oil

Cyclical Consumption and Oil Consumption / Pollution Our planet and its resources are finite. We have to take care and be careful of how Engine / Engen, Hydraulic, Synthetic, or Castrol is disposed. The largest driver that threatens earth and its resources is...